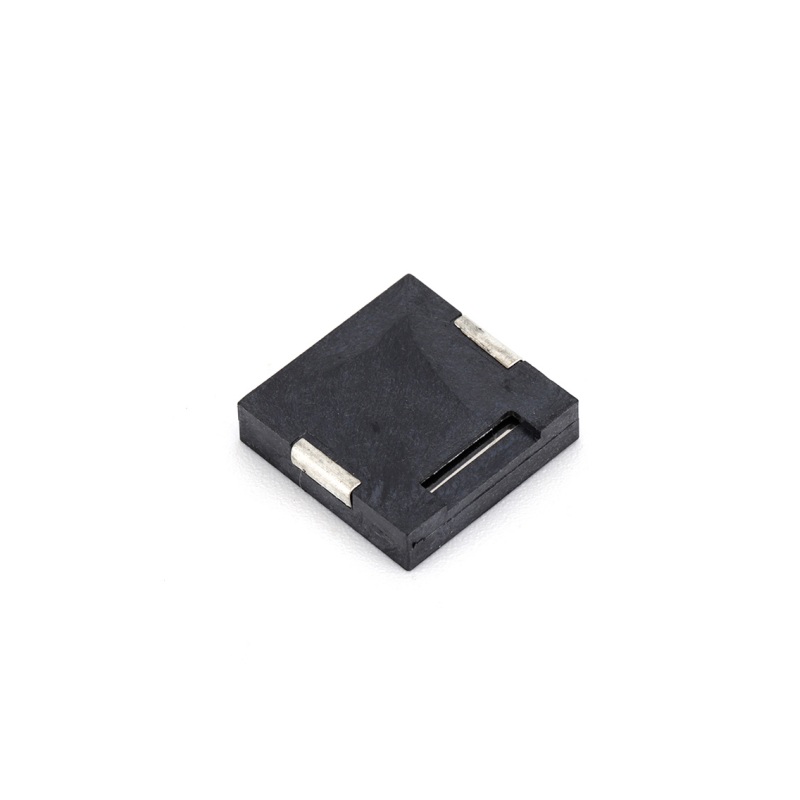

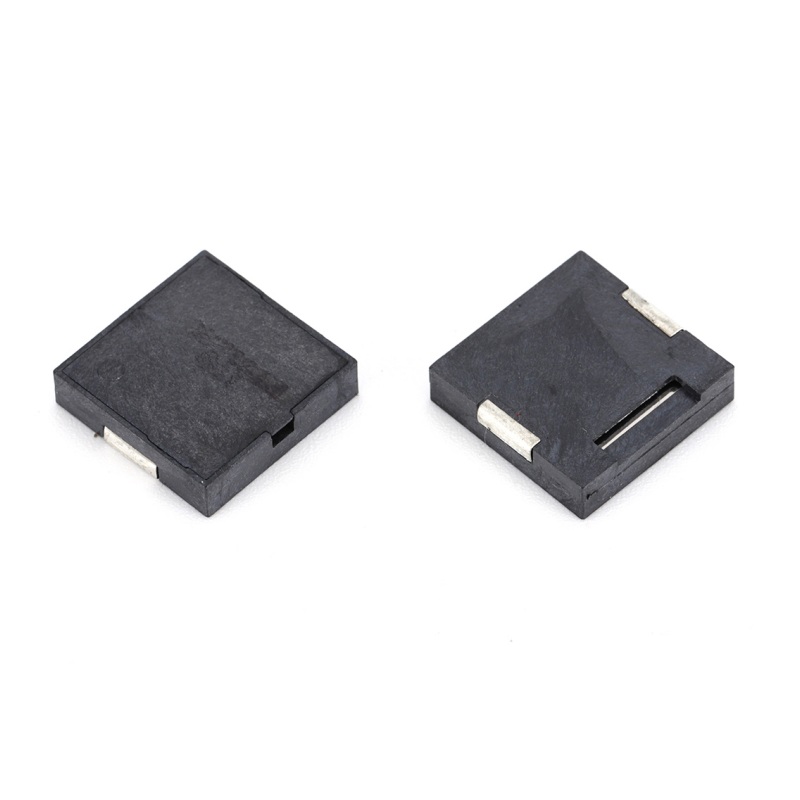

Hydz 12mm Square Smd Type HYG1203A

Electrical Characteristics

| Item | HYG1203A |

| Operating Voltage | Max20Vp-p

|

| Current Consumption | Max 8mA at 12Vp-p/Square Wave/4KHz

|

| Sound Pressure Level | Min 80dB at 10cm/ 12Vp-p/Square Wave/4KHz

|

| Electrostatic Capacity | 16000±30%pF at 1 KHz/1V

|

| Operating Temperature (℃) | -20~ +70

|

| Storage Temperature (℃) | -30 ~ +80

|

| Housing Material | LCP (Black) |

| Dimension | L12.0×W12.0×H3.0mm

|

PS:Vp-p=1/2duty , square wave

Dimensions and Material

Unit:mm Tolerance: ±0.3mm

Taking advantage of extensive acoustic and mechanical design technology and high performance ceramics, SMD piezoelectric sounders suit the thin, high-density design of electronic equipment.

Features

1. 12*12*3mm square smd type

2. Small, thin and lightweight

3. High sound pressure level and clear sound

4. Reflowable

5. Tape & Reel supply

Applications

1. Various office equipment such as PPCs printers and keyboards

2. Home appliances such as microwave oven, rice cookers etc.

3. Confirmation sound of various audio equipment

Notice (Soldering and Mounting)

1. Mounting

When mounting a pin terminal type of product to the printed circuit board, please insert the pin terminal along the hole of the board. If the product is pressed so that the terminal is not in the hole, the pin terminal would be pushed into the inside of the product and the sounds might become unstable.

2. Double-sided through-hole Board

Please avoid using a double-sided through-hole board. If the melted solder touched the base of a pin terminal, a part of the plastic case would melt and the sounds might become unstable.

3. Soldering Conditions

(1) Flow soldering conditions for pin terminal type

· Temperature: within 260°C±5°C

· Time: within 10±1 sec.

· Soldering part is the lead terminals excluding 1.5mm from product body.

(2) Please do not store the products directly on the floor without anything under them to avoid damp places and/or dusty places.

(3) Please do not store the product in places such as in a damp heated place or any place exposed to direct sunlight or excessive vibration.

(4) Please use the products immediately after the package is opened, because the characteristics may be reduced in quality, and/or be degraded in solderability due to storage under poor conditions.

(5) Please be sure to consult with our sales representative or engineer whenever the products are to be used in conditions not listed above.

4. Operating Environment

This product is designed for application in an ordinary environment (normal room temperature, humidity and atmospheric pressure).

Do not use the products in a chemical atmosphere such as chlorine gas, acid or sulfide gas.

Characteristics might degrade by a chemical reaction with the material used in products.

(2) Soldering condition by soldering iron for pin terminal type

· Temperature: within 350±5°C

· Time: within 3.0±0.5 sec.

· Soldering part is the lead terminals excluding 1.5mm from product body

(3) Reflow soldering condition for surface mounting type

· Temperature profile: Fig. 1

· Number of times: Within 2 maximum

4. Washing

Please avoid washing, since this product is not a sealed structure.

5. After Mounting the Product

(1) If the product is floating from the printed circuit board, please do not push it. When pressing, the pin terminal is pushed inside the product and the sounds might become unstable.

(2) Please do not apply force (shock) to the product. If force is applied, the case might come off.

(3) If the case comes off, please do not reassemble. Even if it seems to have returned to the original, the sounds might become unstable.

(4) Please do not blow air onto the product directly. Blown air applies force to the piezoelectric diaphragm through the sound emission hole; cracks could occur and then the sounds could become unstable. In addition, there is a possibility that the case could come off.

Notice(Handling)

1. Piezoelectric ceramic is used in this product. Please use care in handling, because ceramic is broken when excessive force is applied.

2. Please do not apply force to the piezoelectric diaphragm from the sound emission hole. If applying force, cracks occur and the sounds might become unstable.

3. Please do not drop the product or apply shock or temperature change to it. If so, the LSI might be destroyed by the charge (surge voltage) generated.

shows an example driving circuit using zener diode.

Notice (Driving)

1. Ag migration might occur if DC voltage is applied to the product under a high humidity environment. Please avoid using it under high humidity and design the circuit not to apply DC voltage.

2. When driving the product by IC, please insert the resistance of 1 to 2kΩ in series. The purpose is to protect the IC and to obtain stable sound. (Please see Fig. 2a). Inserting a diode in parallel to the product has the same effect. (Please see Fig. 3b)

3. Flux or Coating Agent, etc., Various Solvents It is possible for a liquid solvent to penetrate inside the product, since this product is not a sealed structure. If a liquid penetrated inside and attached to the piezoelectric diaphragm, its vibration could be inhibited. If attaching to an electrical junction, the electric connection might fail.

To prevent sound instability, please do not allow liquid to penetrate inside the product.